National Project on Agricultural Plant Pollution & Invasive Plant Management |

By Bhante Sumitta |

Dhamma USA & Serandib Natures jointly venture this special community care project to benefit many single mothers and underprivileged families in Sri Lanka. This unique project is aimed at empowering the rural economy by reviving the handmade natural paper production project, a product of managing environmentally invasive plants & agro-ecosystems, in line with the world’s new trend of eco-friendly development.

Introduction

This project aims to bring social and environmental benefits to the country by making various useful products using the invasive plants that are currently spreading rapidly in Sri Lanka and discarded plant parts without proper use in agriculture.

In the first phase of the project, 100% natural handmade papers will be produced. Pulp is produced using invasive plant parts and plant parts that are removed from agriculture, and the pulp is used to make natural handmade papers. These natural handmade papers are also used as a raw material to make a variety of useful products. Products such as gift boxes and paper bags are in high demand. These products are made by the hands of rural women and they have the potential to reap huge economic benefits from this.

This project is a great help to the current employment crisis in Sri Lanka. By engaging in this industry, which has a large foreign market, rural women in Sri Lanka have the opportunity to earn foreign exchange without having to go abroad. As a result, it provides the answer to a large number of family crisesThe industry makes up a significant representation of Nepal’s GDP, a country that successfully runs such natural handmade paper projects. It is approximately 10%. A study of this project in Nepal confirms that all countries together supply about 40% of world demand. That means there is another 60% trade space. That is to say, this project will be of great benefit to the national economy of Sri Lanka if such a productive product is made by properly managing the invasive plants and agricultural wastes that are considered to be a nuisance to our country.

In the first phase of the project, income generation will be provided to 50 beneficiary families. The project is expected to be rolled out across Sri Lanka on the emerging market.

Objective

The target group is low income rural women living in rural areas. Those families are socially degraded

due to their economic hardships moving to other areas for employment. Our main objective is to raise

the income level of such people and improve their social and economic status.

● Contribute to the Sri Lankan economy by introducing a Sri Lankan natural product to the world, creating a new industry, saving billions of dollars flowing abroad and replacing the natural hand-made papers and paper related finished products imported to the country from abroad through the newly opened trade space. (Currently, some items such as gift boxes are manufactured in Sri Lanka of low quality, hence a large number of boxes are imported each year, but we have the capacity to produce high quality finished goods at export level.)● To stimulate the production of more such products in our country through the production of eco-

friendly products and to strengthen our broken commitment to the environment among the people.● Our country is also gaining the reputation that several Asian countries such as Nepal and India have

gained through the production of natural handmade papers.

Natural Handmade Paper Production

We use several types of plants to make natural handmade paper. Especially for this purpose, agricultural raw materials and invasive plants are used.

i. Guinea grass (Ali Mana)

Invasive grasses (Guinea grass / Ali mana) are a global problem that reducing farmland, reducing

groundwater levels reduce biodiversity, change ecosystem function, and can increase wildfire

frequency and intensity. These grasses represent a widespread and costly problem in every

Administrative Districts and more broadly in rangelands, and pasturelands across the Sri Lanka.

Such grasses often outcompete and displace native grasses and forbs where they occur, reducing species richness and evenness across large swaths of habitat, often rendering the landscape less suitable for wildlife. By making a useful product from this plant, the plant which has become an environmental problem can be turned into a useful plant.

ii. Water Hyacinth (Japan Jabara)

The water hyacinth plant, an aquatic invasive plant, obstructs waterways, making it impassable for boating, fishing, and all other aquatic activities. The flow of water in these canals has been greatly reduced. An acre of water hyacinth weighs more than 200 tons. It can double in as little as 6-18 days. Once grown on the surface of the water as a cover, the oxygen level in the water is greatly reduced. Therefore, the quality of the water decreases and it also causes the destruction of freshwater fish resources. Biodiversity in freshwater reservoirs is also greatly reduced. Blocking sunlight also affects freshwater aquatic plants.

iii. Banana

Even in banana growing areas as well as in home gardens, the removal of banana stalks left over after

cutting the banana yield has become an extra effort for growers. When those banana stems are not removed, there is a risk of the spread of fungal diseases associated with banana cultivation. But when there is a demand for this plant part through this production process, there is an automatic solution to the problem faced by the growers.

Also, soft-fiber plant parts that are commonly found can be used without harming the environment

Natural handmade paper production process – Traditional Method

Cleaning of impurities in plant parts

This is done by removing and cleaning the dirt that has joined the cut plant parts.

Cutting of cleaned plant parts

What is done here is to cut the cleaned plant parts into small pieces.

Boil the cut plant parts

Here the plant parts cut into thin pieces are boiled.

Washing boiled plant parts

The boiled plant parts are thoroughly washed and the fibrous part is separated.

Making the pulp

The boiled and washed plant fibers are separated and ground into

a beater to make pulp. In this case the desired natural or artificial

colors and natural binding material made from plant extracts are

added.

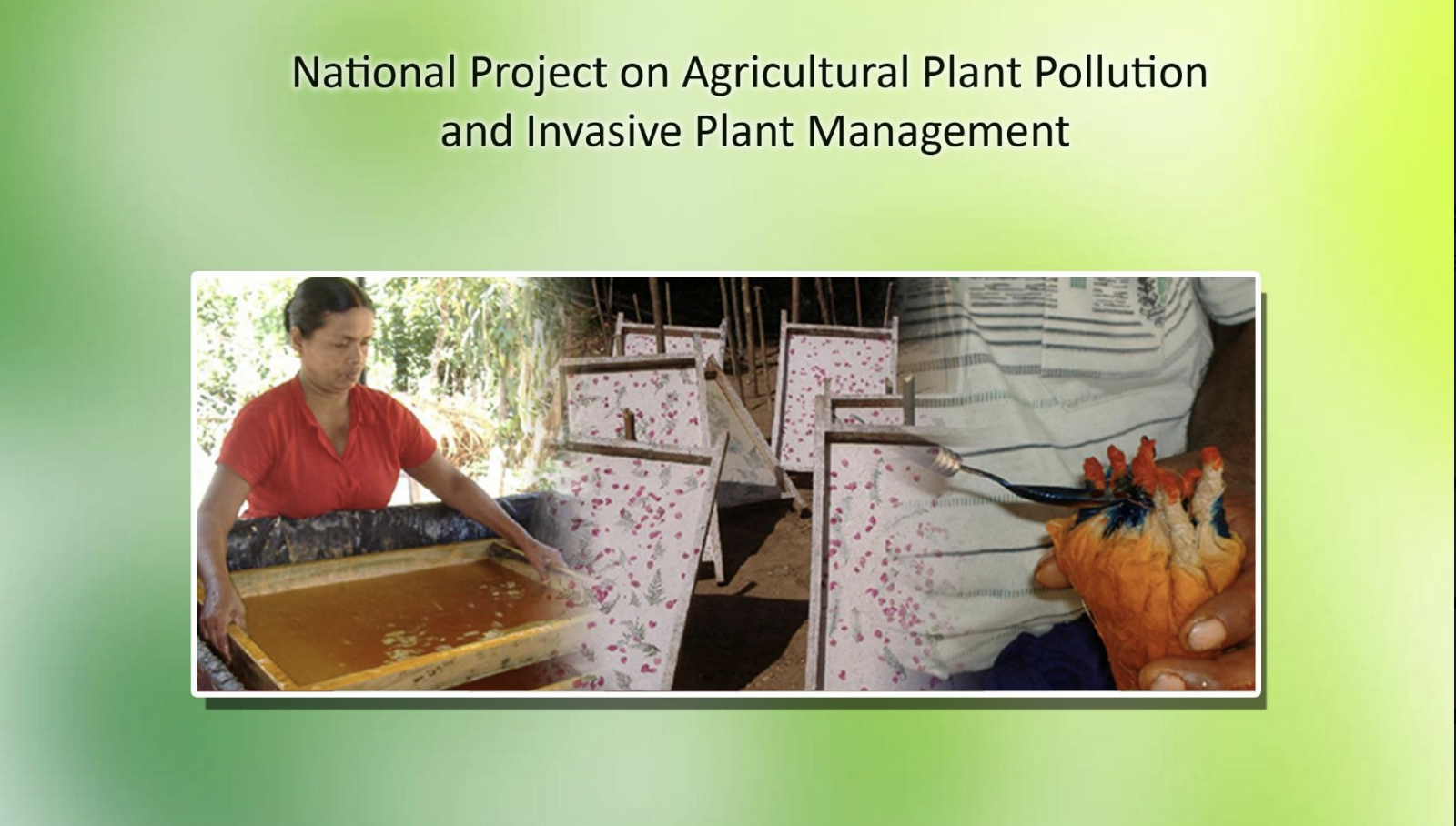

Making natural handmade papers from pulp

The prepared pulp is immersed in a water tank and placed in a mesh wooden frame, where the

paper is processed and basically dried in the sun to create the papers. In this case different types

of papers are produced by applying the required designs.

Finishing the manufactured papers

The final product is obtained by inserting it into the

calendar machine and pressing it to give a high

finish to the originally designed papers.

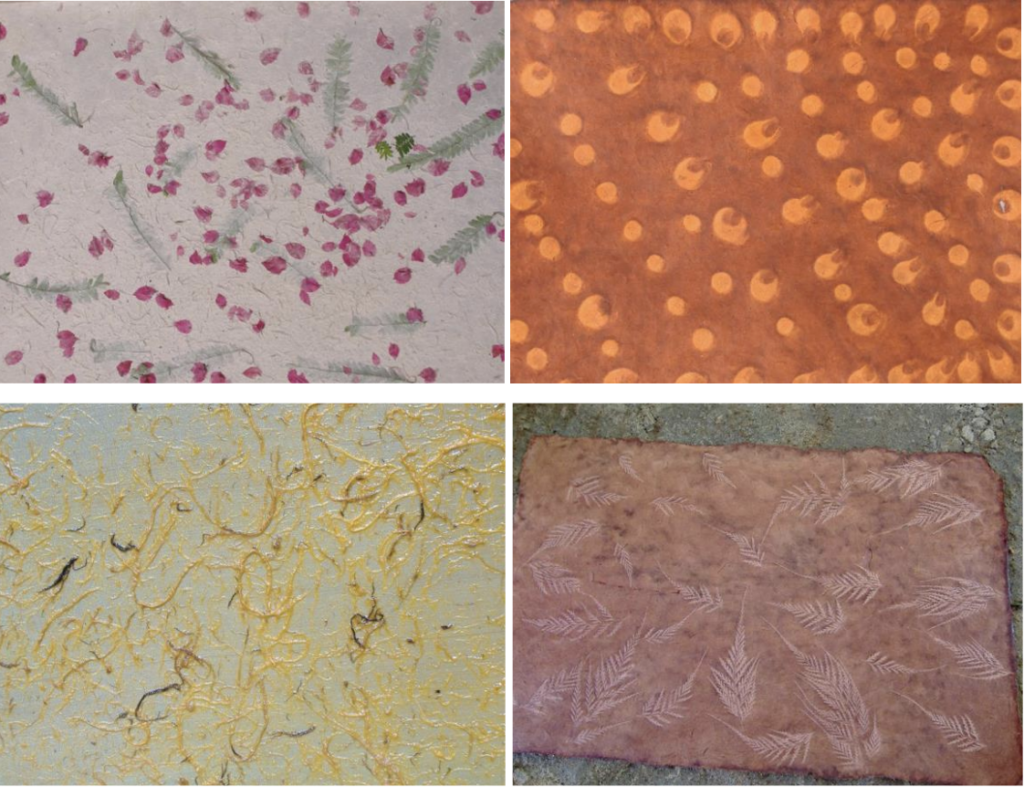

Applying designs to finished papers

Patterns can also be applied to finished papers. Here too, high quality papers can be produced with

different values.

Several different types of papers produced

Uses & Benefits

There are a number of uses and benefits that we have outlined in Chapter 2 Objectives. If they are further described,

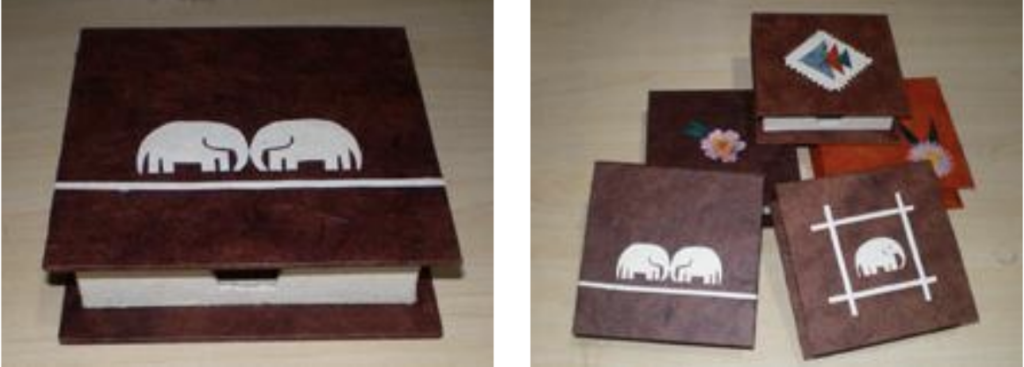

4.1. Uses

Widely used for a variety of value-added products such as various decorations, invitations and its wraps,

paper handbags, natural flower packaging, gift wrapping, packing boxes, stationary items.

4.2. Current demand

Currently there is a huge demand for natural handicrafts in the local and foreign markets. Also,

foreign tourists visiting this country have a special interest in purchasing handicrafts made in the

rural areas of our country.

● This opens up a good market space for natural handicrafts as well as their finished products. This

space is being further expanded due to the new interest in developed countries in eco-friendly

natural products.

● Locally educated and eco-friendly people are tempted to buy eco-friendly products and some

people who make a living from paper-based products to cater to their needs. But they cannot buy

the natural handmade papers they want imported from abroad in the local market. Although they

are expensive.

● At present, these handmade paper products are used locally for imported products, so it is possible

to supply products for that demand.

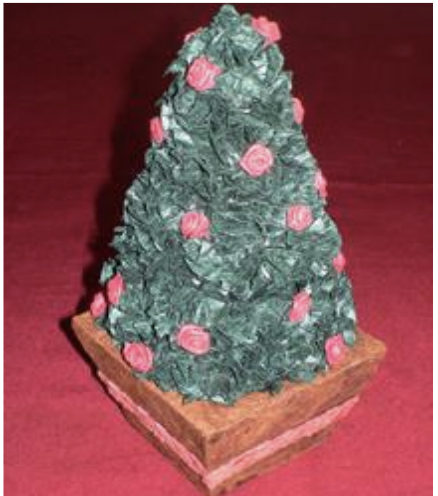

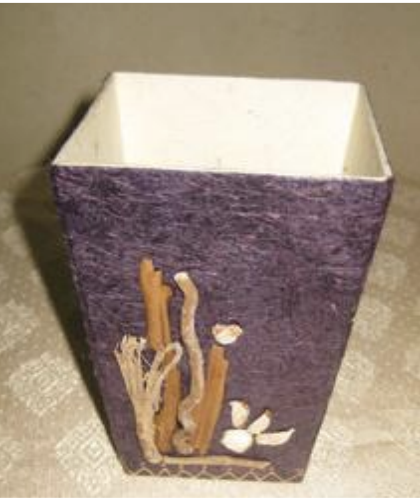

Here are some products that are made from natural handmade papers

Pencil Boxes

Paper Bags

Flower Arrangement

Chit Boxes

Light Boxes and Lamp Shades

Christmas tree

Vasses

Photo Frames

4.1. Environmental benefits

Ali Mana (Guinea Grass), an indestructible plant present in Sri Lanka, causes a number of

environmental problems such as destruction of plantations, forest fires, and narrowing of irrigation

canals. To. It is possible to remove alimana plants in an area of about 100 square feet by producing

about 70 handmade papers per day.

● Even in banana growing areas as well as in home gardens, the removal of banana stalks left over

after cutting the banana cans has been a laborious task for the growers. When those banana stems

are not removed, there is a risk of the spread of fungal diseases associated with banana cultivation.

But when there is a demand for this plant part through this production process, there is an

automatic solution to the problem faced by the growers. It is possible to remove about five

discarded banana plants by producing about 70 handmade papers per day.

● Japan jabara (water hyacinth) can be identified as an invasive plant found in Sri Lankan lakes. Due

to the unrestricted spread of this plant, there is a risk of flooding of reservoirs and depletion of

fresh water fisheries. As a solution to this, paper can be produced in tank areas. This has the

potential to generate additional revenue for the community. Producing about 70 handmade papers

a day, it is possible to remove Japan jabara (water hyacinth) plants in an area of about 200 square

feet.

● At present, polythene and ordinary papers are widely used in many products in Sri Lanka, including

handbags and invitations. But the promotion of these eco-friendly products also benefits the

environment with minimal use of the above products.Although this natural handmade paper is disposed of in the environment, it does not contain

synthetic chemicals, so it does not harm the environment.

● It is also possible to make organic fertilizer using plant parts discarded from paper. It also indirectly

supports organic farming in Sri Lanka.

4.2. Social benefits

This production process is done with the labor contribution of the rural communities in the rural

areas and has the potential to improve their low-income living standards. It targets rural poor

women.

● Sri Lankans have historically been highly creative and have the ability to use their creativity in these

handicrafts to create a community with high mental potential through the development of their

creative and entertaining side.

● Dyes and gums used in the manufacture of paper are currently available in the market and most of

them are made from natural materials. However, in the future, we hope to launch research to

produce the traditional knowledge and experience of the rural people of Sri Lanka in our own

country.

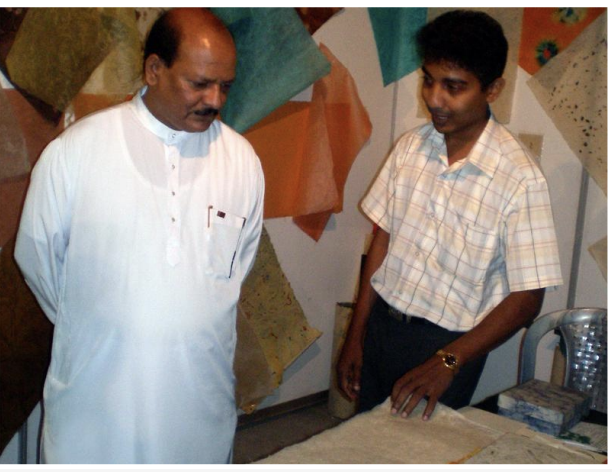

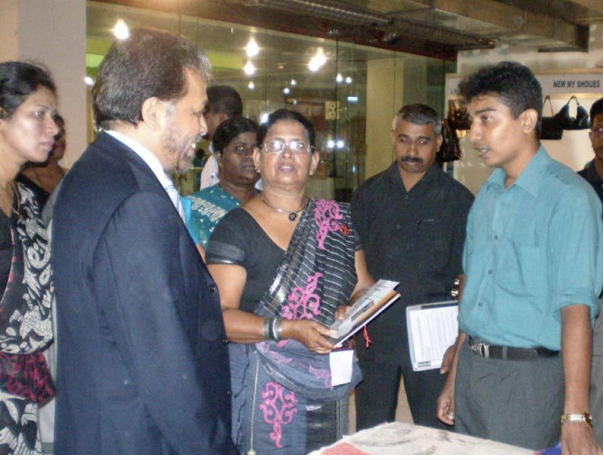

5.2. Industry appraisal

The “Hands Lanka 2009” exhibition organized by the Sri Lanka Chamber of Commerce at the Kandy City

Center, Kandy from 1st to 4th August 2009 was well received by local and foreign businessmen.

At the exhibition in Kandy City Center, Kandy in August 2009

Natural handmade papers on display.

Hon. Sarath Ekanayake, then Chief Minister of the Central Province inspecting natural handmade papers

The then Secretary to the Foreign Ministry Palitha Kohona inquiring about the production of natural handmade papers

How a group of foreign businessmen who came to see the exhibition looking the natural handmade papers

Chamber of Commerce officials inquiring about new experience in natural paper production

People who came to see natural paper asking about this

In October 2009, an exhibition organized by the National Crafts Council to introduce local and foreign buyers to the handicraft manufacturers at the Queen’s Hotel in Kandy attracted a large number of local and foreign entrepreneurs and the demand from them reached a level where production capacity was failing.

These industrial products also attracted a lot of attention at home and abroad at the ‘Shilpa 2009’ exhibition organized by the National Crafts Council and the Industrial Development Board at the BMICH from 26 to 30 November 2009. It was a special occasion for the Swissterland Ambassador to Sri Lanka to visit the exhibition and receive a special appreciation of these products.

For More Info & Orders:

email Dhamma USA | info@dhammausa.com